Oral Presentation International Solvent Extraction Conference 2025

Influence of Wall Contact on the Sedimentation Behavior of Drops in Structured Packing Channels (121178)

Introduction

Currently, the design of liquid-liquid extraction columns primarily relies on experimental methods, which are often costly and time-consuming. One potential solution is to support this design process through column modeling techniques such as Computational Fluid Dynamics (CFD) or Drop-Population-Balance-Models. However, these approaches require correlations that accurately represent phenomena within the columns, including coalescence, breakage, mass transfer, and drop sedimentation. [1,2]

An analysis of existing correlations for drop sedimentation in structured packing columns reveals several limitations. Semi-empirical correlations derived from single drop experiments typically consider the complex geometry of structured packings by incorporating only geometric parameters like packing height, volumetric surface area, and number of channels. However, they often overlook crucial factors such as the type of packing material used, complex channel geometries, and counter-current flow dynamics. [3–6]

Notably, the pronounced drop-wall contact within structured packing channels significantly influences drop velocity reduction [3,7]. Additionally, experiments conducted in various extraction column types—such as disk and donut, Karr, and sieve plate columns—demonstrate that different internal materials affect fluid dynamics, such as hold-up and wettability characteristics of internals [8–10]. Consequently, there is a pressing need to establish a more comprehensive understanding of how packing material and geometry influence these drop-wall interactions to develop accurate correlations for drop sedimentation in packings.

Given that direct observation inside structured packings is not feasible and as of now only the integral velocity of a drop entering and leaving a packing has been measured [3,11,12], we propose an optically accessible measurement cell designed to investigate drop-wall interactions under counter-current conditions with both single-wall and two-wall (channel) contact. With our setup, we can specifically investigate the influence of packing parameters such as material, channel angle and width on drop behaviour on surfaces and sedimentation velocity. These parameters have so far only been considered collectively due to the integral measurement method during entry and exit from the packing.

Experimental Facility

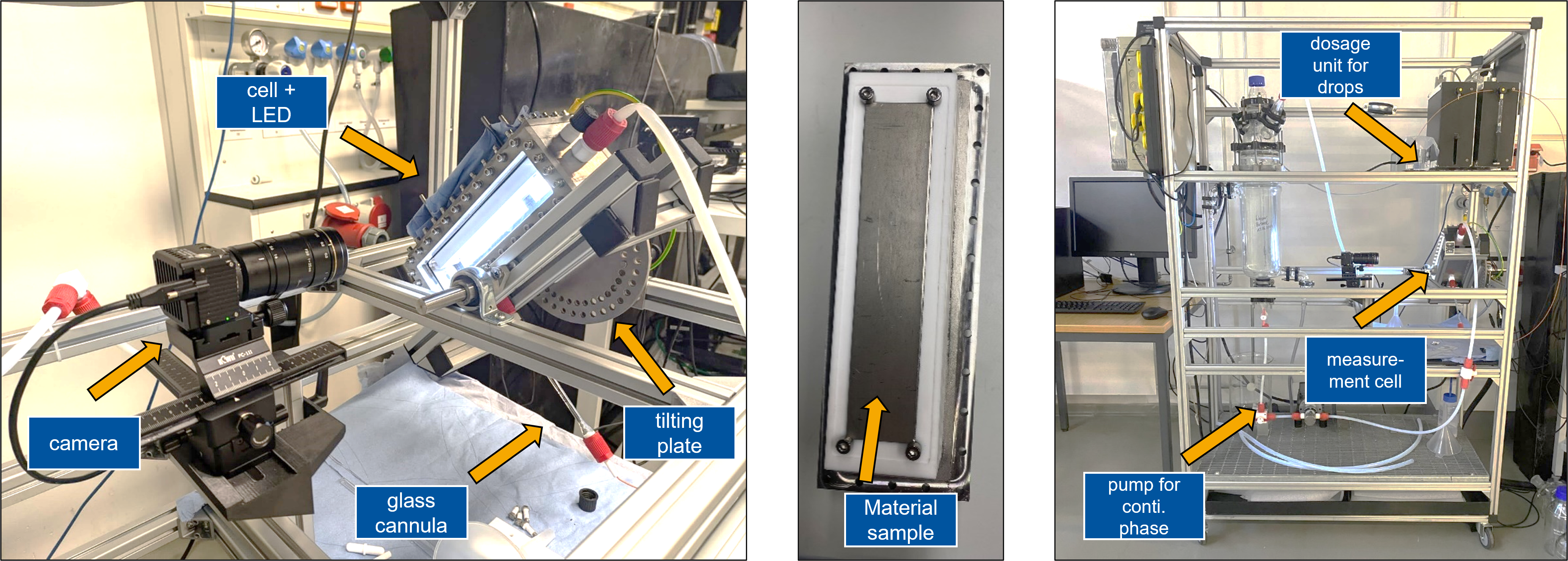

Figure 1 illustrates the measuring cell. In this optically accessible cell we can investigate the movement of the organic drop and its interactions with different surfaces under aqueous counter-current conditions. The influence of single-wall and two-wall contact as well as the influence of the distance between two walls, representing the channel width, can be investigated. Tilting the cell simulates various channel angles (30-60°) found within structured packings [12]. The camera setup includes a 5K wide-angle camera paired with an LED light source recording at a frame rate of 200 fps.

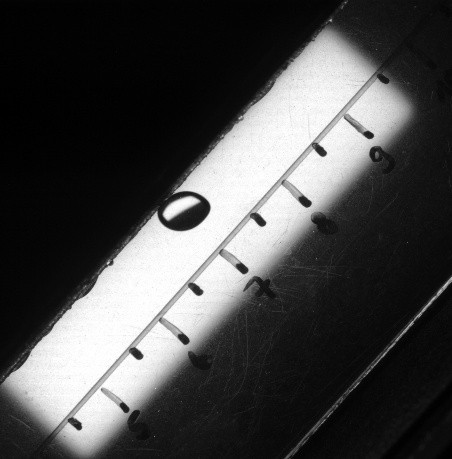

The image sequence is evaluated using an in-house developed Python program. This tool analyses the contact line of the drop on the surface along with the drop shape. Additionally, it tracks the drop's centre over time to calculate its velocity. Figure 2 shows an exemplary image of a drop moving along a 45° inclined stainless steel surface.

Figure 1: Set-up of cell.

Figure 2: Drop moving along surface.

Results and Discussion

We investigated various organic drop-wall interactions using stainless steel and PTFE surfaces under both single-wall and two-wall contact conditions by varying organic solvents and their drop sizes. The results were compared with velocities and shape behaviours of freely rising drops. The experiments revealed that adding a single inclined wall reduced drop velocity by up to 40% compared to free rising drops. This decrease was even more pronounced when adding a second wall or varying channel width. Due to wall contact, the drop shape is stabilized while oscillatory behaviour typical of larger free rising drops was suppressed. This factor can influence mass transfer during extraction.

A comparison between our experimental data and integral velocities of single drops in structured packings indicates that introducing a single wall leads to drop velocities in the same order of magnitude. This finding shows that using this simplified setup, first indications regarding drop behaviour within structured packings can be provided.

Conclusion

Our investigations demonstrate that single- and two-wall contact significantly influence drop sedimentation behaviour. Additionally, this simplified measurement cell provides valuable insights into velocities that can be expected within structured packings. Future research will focus on investigating additional materials along with their surface structures. The goal is to establish a workflow for precise CFD modeling of drop sedimentation based on experimental data obtained from this measurement cell to support structured packing design in the future.

- [1] Bart, H.-J.; Jildeh, H.; Attarakih, M. Population Balances for Extraction Column Simulations—An Overview. Solvent Extraction and Ion Exchange 2020, 38, 14–65.

- [2] Weber, B.; Jupke, A. Compartment-model for the simulation of the separation performance of stirred liquid–liquid-extraction columns. AIChE Journal 2020, 66, e16286.

- [3] Garthe, D. Fluiddynamics and Mass Transfer of Single Particles and Swarms of Particles in Extraction Columns. Dissertation, Technische Universität München, 2005.

- [4] Mao, Z.-Q.; Godfrey, J. C.; Slater, M. J. Single liquid drop velocities and breakage mechanism in sections of structured packings. Chem Eng & Technol 1995, 18, 33–40.

- [5] Maćkowiak, J. Grenzbelastung von unpulsierten Füllkörper‐Kolonnen bei der Flüssig/Flüssig‐Extraktion. Chemie Ingenieur Technik 1993, 65, 423–429.

- [6] Seibert, F.; Reeves, B.; Fair, J. R. Performance of a large-scale packed liquid-liquid extractor. Ind. Eng. Chem. Res. 1990, 29, 1901–1907.

- [7] Kögl, T. Tomographische Untersuchungen in der flüssig-flüssig Extraktion. Dissertation, Friedrich-Alexander-Universität Erlangen-Nürnberg, 2021.

- [8] Christo, R.; Shen, S.; Stevens, G. W. Effect of Plate Material on Dispersed-Phase Holdup in a Karr Reciprocating Plate Column. Solvent Extraction and Ion Exchange 2011, 29, 800–822.

- [9] Grabin, T.; Smith, K. H.; Mumford, K. A.; Wang, Y.; Stevens, G. W. Effect of Plate Wettability on Dispersed-Phase Holdup in a Pulsed Disc-and-Doughnut Solvent Extraction Column. Solvent Extraction and Ion Exchange 2017, 35, 573–585.

- [10] Ikeda, H.; Suzuki, A. Wettability Effects of Plate Materials on Hydrodynamics in a Pulsed Perforated-Plate Extraction Column of Pulser Feeder Type. Ind. Eng. Chem. Res. 1995, 34, 4110–4117.

- [11] Hoting, B. Untersuchungen zur Fluiddynamik und Stoffübertragung in Extraktionskolonnen mit strukturierten Packungen; Fortschritt-Berichte / VDI Reihe 3, Verfahrenstechnik 439; VDI-Verl.: Düsseldorf, 1996.

- [12] Leu, J. T. Beitrag zur Fluiddynamik von Extraktionskolonnen mit geordneten Packungen: Fortschritt-Berichte, VDI-Reihe 3 Nr. 413, 1. Auflage; VDI Verlag: Düsseldorf, 1995.

- Abstract category selection: