Oral Presentation International Solvent Extraction Conference 2025

Droplet Size Distribution and Hydrodynamic Optimization in the Lithium-Ion Battery Recycling Process Using TENOVA’s Reverse-Flow Mixer-Settler (121759)

The solvent extraction (SX) process plays a crucial role in the recycling of lithium-ion batteries (LIBs), particularly in the separation and purification of valuable metals such as cobalt and nickel as well as Lithium. One of the key challenges in SX operations is optimizing settler performance to ensure efficient phase separation while minimizing entrainment and improving mass transfer efficiency. Droplet Size Distribution (DSD) is a critical parameter influencing the hydrodynamics of the settler, affecting both phase disengagement and the overall efficiency of metal recovery.

In this study, droplet size distribution was measured in three different SX circuits within a LIB recycling process. The primary objective was to establish a correlation between droplet size and the physical properties of the organic and aqueous phases to the hydraulic performance of the settler. Understanding these relationships is essential for optimizing industrial settler operation, enhancing phase separation efficiency, and enabling more effective scale-up of SX circuits. By improving settler performance in industrial Reverse Flow Mixer-Settler (RFMS) units, this research aims to increase design flux, reduce entrainment losses, and ultimately minimize the required settler footprint and overall process costs.

The LIB recycling process involves multiple SX circuits, each employing distinct extractants tailored to specific metal separations. Among these, the most critical circuits: impurities SX, cobalt SX, nickel SX, and lithium SX each of which operates under different chemical conditions and utilizes extractants with varying physical properties such as viscosity, interfacial tension, and density. The experiments were conducted using pregnant leach solution (PLS) obtained from LiB black mass after the leaching stage, ensuring that the study accurately reflects real industrial conditions.

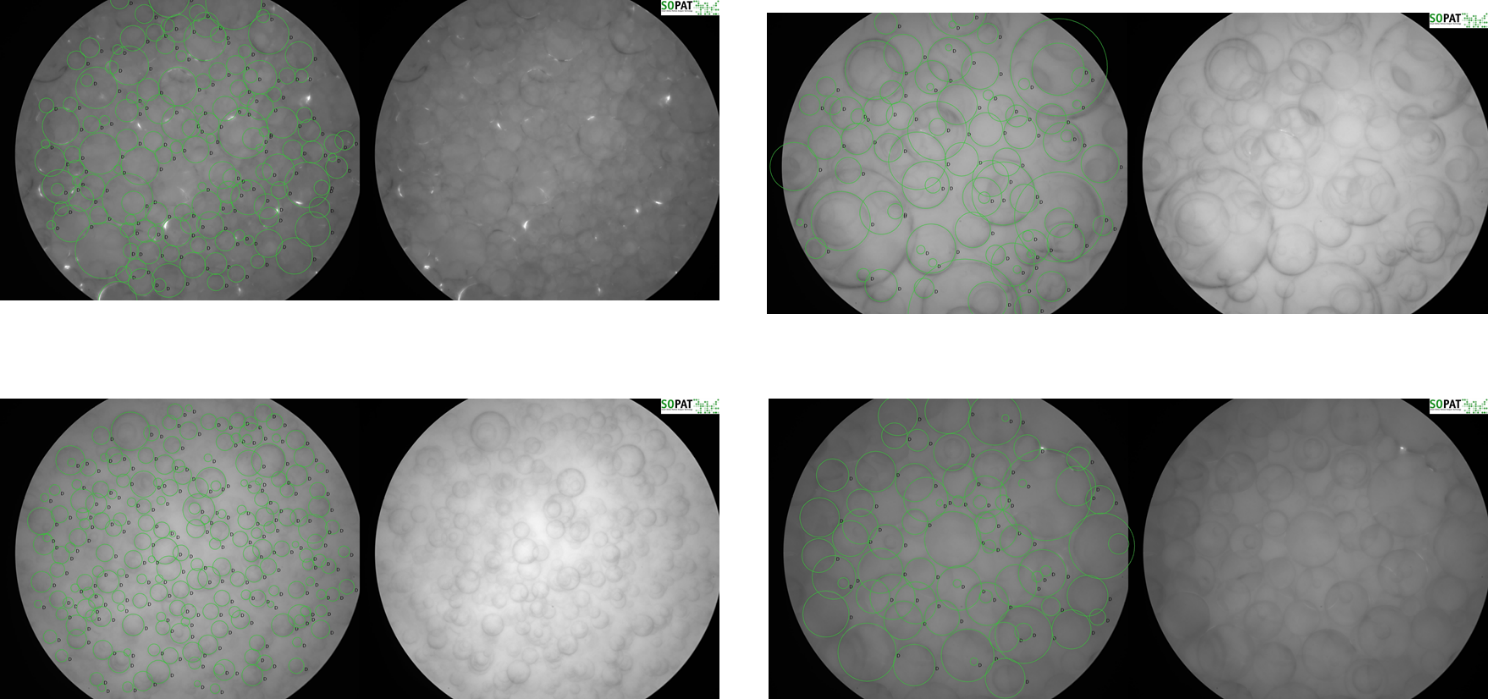

Experiments were conducted using the hydraulic test mixer-settler system at the TAT R&D facility. Droplet size was monitored in each SX circuit at both the primary pump mixer and secondary hydrofoil impeller mixer under varying process conditions using SOPAT in-line imaging technology Kr microscopic probe, providing high-resolution, real-time data on droplet size distribution. In parallel, hydrodynamic data were collected from the settler, including dispersion layer thickness and entrainment levels. These measurements were used to assess how key operational parameters influence settler performance and overall metal recovery efficiency.

Key parameters investigated in this study include:

- Phase continuity

- Mixing phase ratio

- Mixer residence time

- Physical properties

- Impeller type and agitation speed

DSD was analyzed using SOPAT image analysis DNN (Deep Neural network) algorithm tailor made workflow. The results demonstrate the differences in the behaviour of the three SX systems, reflected in both distinct DSD and hydrodynamic performance. A 25% decrease in the Sauter mean diameter (D32) was observed with a reduction in the dispersed-to-continuous phase ratio (D/C). Additionally, transitioning from a pump mixer impeller to a secondary hydrofoil impeller resulted led to a 45% increase in the Sauter mean diameter, emphasizing the role of two mixers design in phase separation efficiency. The shift from aqueous to organic phase continuity was clearly observed, and the system was found to reach hydraulic equilibrium within approximately 60 seconds, with the DSD stabilizing within the mixers. A correlation between change in DSD and the hydraulic performance was demonstrated.

The findings from this study provided valuable insights into the impact of droplet size on phase separation efficiency and settler hydrodynamics. By identifying optimal operating conditions, this research supports the development of improved SX circuit designs, enabling better scalability, and enhanced process stability in industrial applications. Furthermore, the correlation between droplet size distribution and hydraulic performance can serve as a predictive tool for designing RFMS with reduced entrainment losses and improved throughput.

The next phase of this research will focus on utilizing the collected data to develop a predictive model for settler hydrodynamics, allowing for the optimization of process parameters based on real-time droplet size measurements. By integrating experimental results with computational modelling approaches, this study aims to narrow the gap between laboratory experiments, pilot scale, and full-scale industrial implementation, ultimately contributing to the advancement of more efficient and sustainable LIB recycling processes.

- Abstract category selection: