Oral Presentation International Solvent Extraction Conference 2025

An Automated Multimodal Platform for Liquid-Liquid Partition Measurements Aided by Computer Vision (122336)

Liquid-liquid partition coefficient is one of the fundamental properties for drug discovery, process development and bio-downstream separation [1]. Traditional way to measure partition coefficient is by shake-up experiments, which consumes large volume of reagents and often time consuming. In recent years, lab automation and machine learning have significantly advanced scientific discovery and accelerated process development. These technologies enable rich data collected from experiments and streamlined analysis to extract useful information, which could improve the efficiency of liquid-liquid extraction development process.

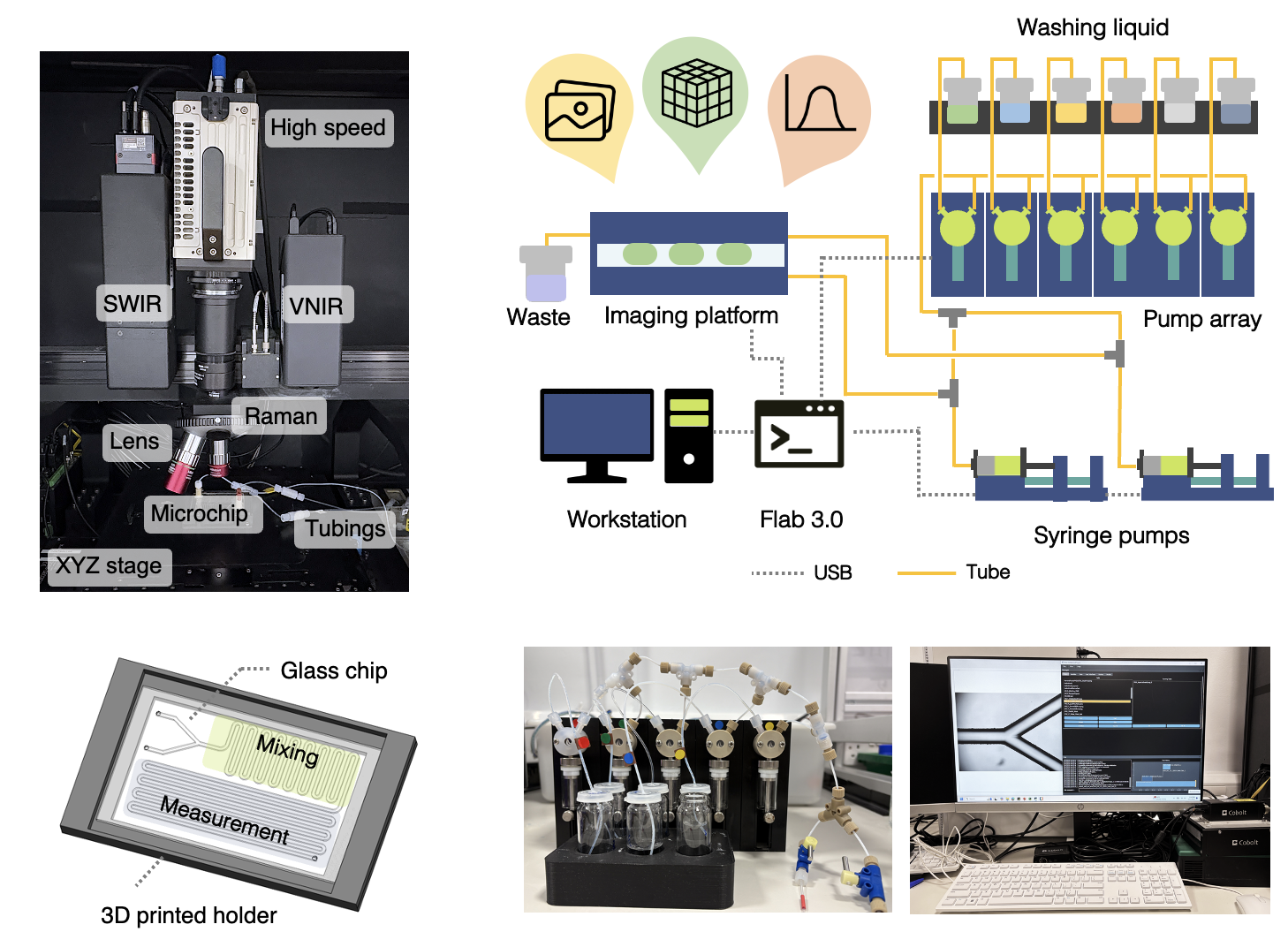

To address this, an automated experimental platform is developed for monitoring and measuring partition process of liquid-liquid systems (Figure 1). The system mainly consists of an imaging system with a PC, a microchip and a pumping system. The imaging system consists of multiple detectors: a high-speed camera, two visible and near infrared hyperspectral cameras (SWIR and VNIR) and Raman spectroscopy. A glass microchip is mounted on a XYZ translation stage, and is connected to the pump system via PTFE tubing, which allows two liquid phases to be introduced and generate droplets to travel in the channel. The pumping system consists of a pump array for cleaning the channel with washing liquids. Two syringe pumps are applied for transporting the testing liquids into the channel. The pump system and the imaging system is synchronised by Flab [2], which is a python-based framework allows for automating the experimental procedures.

Figure 1. Automated experimental setup for measuring liquid-liquid partition coefficient

The measurement process begins with automated cleaning and rinsing of the microchip using ethanol and water. Then the high-speed camera starts capturing the fluid condition inside the channel, with a machine-learning based classifier to detect droplet flow. This is followed by image analysis to extract slug sizes and moving velocity from the consecutive images. Based on this hydrodynamics information, imaging settings such as the capture locations for hyperspectral camera or integration time for Raman measurements are adjusted and the concentration measurements then start. The solute concentrations in each phase are determined through spectral analysis, where peak intensities are extracted and used to calculate partition coefficients. The measurement repeats multiple times for improved accuracy and followed by a final washing step.

Based on the experimental platform, we have successfully measured partition coefficients for various liquid-liquid systems. The measurement of partition coefficient is fully automated and due to the fast mass transfer of the microchip, the entire measurement is less than 15min per test system. This approach significantly reduces human intervention and accelerates the measurement process, demonstrating the potential of integrating automation and machine learning for fast partition coefficient analysis.

- Leo A, Hansch C, Elkins D. Partition coefficients and their uses. Chemical reviews. 1971, 71(6):525-616.

- Jose NA, Adesina P, Ballu K, Chitre A, Karan D, Katsarou A, Pomberger A, Zhai S, Lapkin A. A Universal Framework for Fast, Flexible and Fun(ctional) Autonomous Laboratories. Arxiv, 2024, 10.26434/chemrxiv-2024-990q0.

- Abstract category selection: