Oral Presentation International Solvent Extraction Conference 2025

Model-Based Performance Monitoring and Optimization for the Autonomous Operation of Liquid-Liquid Extraction Columns (122655)

Background

Liquid-liquid extraction is an established low-energy separation process used in a wide range of industrial applications for the separation of temperature-sensitive components, aqueous solutions and azeotropic mixtures. Specifically, the separation of platform chemicals, e.g., acetic acid[1], has been shown to be up to 80% more energy-efficient in liquid-liquid extraction columns (LLECs) compared to conventional rectification[2]. However, trace elements found in recycling- and bio-based process streams, e.g., solid microparticles, proteins, and salts, significantly disturb the coalescence behavior of solvent drops inside LLECs[3]. The disturbance of coalescence behavior by trace elements is highly complex and nonlinear and induces fluctuating fluid dynamic states within LLECs, e.g., drop size distribution, dispersed phase hold-up, and sedimentation velocity[3]. These fluid dynamic states affect the mass transfer rate and thus the LLEC’s separation performance[4]. As a result, the solvent flow rate and the energy input necessary to complete the separation task fluctuate significantly due to trace elements[5].

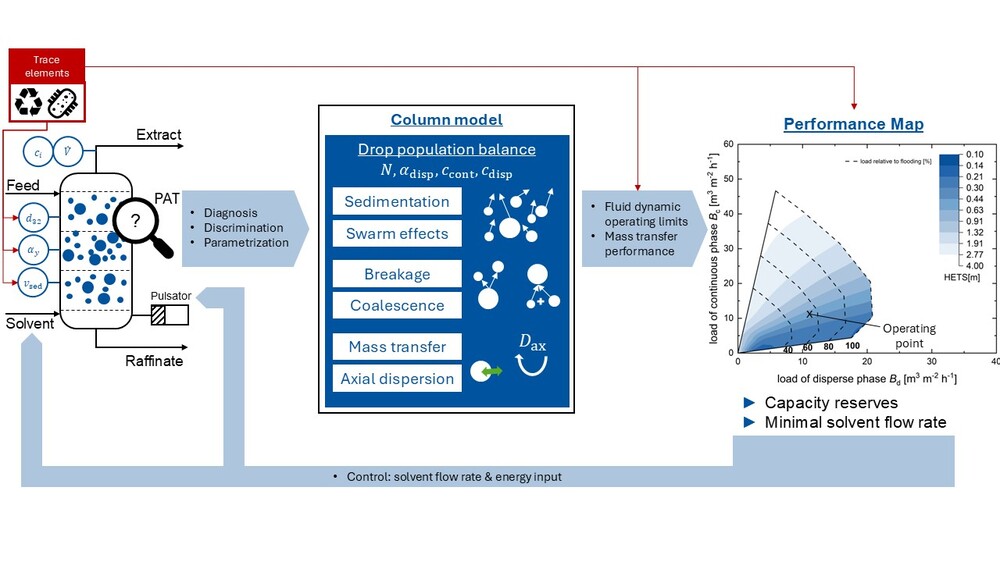

To adapt solvent flow rate and energy input based on fluctuating fluid dynamic states and thus achieve flexible LLEC operation, advanced model-based feedback control is necessary[6,7]. The implementation of model-based feedback control systems requires process analytical technology (PAT) that measures fluid dynamic states within LLECs, and high-fidelity models that predict fluid dynamic operating limits and mass transfer performance as a function of solvent flow rate, energy input, and fluid dynamic states[8]. The combination of PAT and high-fidelity models enables the identification of capacity reserves and the minimal solvent flow rate necessary to complete the separation task, the adaptation of solvent flow rate and energy input, and consequently, the flexibilization of LLEC operation[5]. Ultimately, flexible operation by model-based feedback control reduces solvent usage and thus energy expenses for solvent recovery rectification[5].

Methods

We equipped a DN50 pulsed sieve plate extraction column with extensive PAT suitable for measuring fluid dynamic states in LLECs and recording coherent experimental data for model development. A differential pressure sensor, two high speed cameras with telecentric lenses, and four Coriolis flow meters were installed to simultaneously measure the dispersed phase holdup, drop size distributions, sedimentation velocities, and flow rates of all substances.[9]

To develop a hybrid model based on a 1-dimensional drop population balance and submodels for fluid dynamic phenomena, we acquired comprehensive experimental data on drop breakage[10] and coalescence[11], and compiled an optimization approach for regressing the corresponging model parameters[11]. By combining data-driven and physics-based modeling concepts, we aimed at deriving a hybrid model that is accurate over a broad range of physical properties and operating conditions.

A comprehensive experimental campaign was carried out with water/acetone/n-butyl acetate, a standard test system proposed by the EFCE[12]. Focus of this study was the dependency of mass transfer performance on fluid dynamic states inside the LLEC over a wide range of operating conditions, e.g., energy input and liquid load.

Building upon our hybrid modeling approach for fluid dynamics[11], we extended the 1-dimensional population balance by mass transfer models to accurately depict our experimental datasets. Throughout model discrimination and development, a trade-off between model accuracy and computational time was considered to ensure suitability for model-based feedback control.

Results&Conclusions

We developed data-driven parameter estimators for drop breakage[11] and coalescence phenomena[12], which enhance the conventional physics-based models for breakage and coalescence that are implemented in our 1-dimensional drop population balance. The enhancement of physics-based models with data-driven parameter estimators enables the prediction of drop sizes with increased accuracy over broad ranges of physical properties, column geometries, and operating conditions.

The results of our experimental campaign suggest that, based on fluid dynamic measurements[9], the solvent drops’ residence times, mass transfer areas, and mass transfer resistances can be derived and further utilized for mass transfer model discrimination and development. As a result of mass transfer model discrimination and development, we extended our hybrid modeling approach for fluid dynamics by the two-film mass transfer model. Calculating the mass transfer resistances in both phases based on fluid dynamic measurements inside the LLEC enables the prediction of separation performance with sufficient accuracy over a wide range of operating conditions.

The hybrid model’s computational time lies within minutes, thus we conclude that our 1-dimensional population balance combining data-driven parameter estimators for fluid dynamics with the two-film mass transfer model will be suitable for model-based feedback control.

- [1] A. Bokhary, M. Leitch, and B. Liao. “Liquid–liquid extraction technology for re-source recovery: Applications, potential, and perspectives”. In: Journal of Water Pro-cess Engineering 40 (2021), p. 101762.

- [2] K.-L. Li, I.-L. Chien, and C.-L. Chen. “Design and optimization of acetic acid de-hydration processes”. In: Proceedings of international conference on advanced con-trol of industrial processes (ADCONIP 2014), Hiroshima, Japan. 2014, pp. 126–31.

- [3] J. Kamp, J. Villwock, and M. Kraume. “Drop coalescence in technical liquid/liquid applications: A review on experimental techniques and modeling approaches”. In: Reviews in Chemical Engineering 33.1 (2017).

- [4] A. Fells, A. De Santis, M. Colombo, D. W. Theobald, M. Fairweather, F. Muller, and B. Hanson. “Predicting mass transfer in liquid–liquid extraction columns”. In: Processes 10.5 (2022), p. 968.

- [5] A. Palmtag, and A. Jupke. Performance Monitoring and Optimization of Extraction Columns By a Hybrid Modeling Approach. In: 2023 AIChE Annual Meeting. AIChE.

- [6] E. N. Pistikopoulos, N. A. Diangelakis, R. Oberdieck, M. M. Papathanasiou, I. Nascu, and M. Sun. “PAROC—An integrated framework and software platform for the optimisation and advanced model-based control of process systems”. In: Chemi-cal Engineering Science 136 (2015), pp. 115–138.

- [7] V. Vanel, J. Mallet, B. Dinh, S. Michaud, M. Montuir, and F. Vilpini. “Predictive functional control for separation processes by liquid-liquid extraction”. In: Frontiers in Chemical Engineering 5 (2024), p. 1294784.

- [8] M. W. Hlawitschka, et al. "Digital extraction column: measurement and modeling techniques." Chemie Ingenieur Technik 92.7 (2020): 914-925.

- [9] A. Palmtag, et al. “Towards the Digital Extraction Column: Online-Monitoring and Analysis of Fluid Dynamics in Liquid-Liquid Extraction Columns." In: Chemical En-gineering Journal Advances (2025): 100727.

- [10] A. Palmtag, et al. "Hybrid modeling of drop breakage in pulsed sieve tray extrac-tion columns." In: Frontiers in Chemical Engineering 5 (2023): 1274349.

- [11] A. Palmtag, et al. "Hybrid modeling of liquid-liquid pulsed sieve tray extraction columns." In: Chemical Engineering Science 287 (2024): 119755.

- [12] Misek, T., R. Berger, and J. Schröoter. "European Federation of Chemical Engi-neering." Recommended Systems for Liquid Extraction Studies, The Institute of Chemical Engineers (1978).

- Abstract category selection: