Poster Presentation International Solvent Extraction Conference 2025

SisClever process: simultaneous recovery of metals from ore or waste to high purity and high concentration via solvent extraction – experimental validation (#103)

Efficient recycling of valuable metals is critical to the sustainable use of resources, given their role in advanced technologies such as batteries and high-performance magnets. The SisClever process offers an efficient alternative to traditional multi-step separation processes. This is a single counter-current process that allows to separate, in principle, an arbitrary number of components, by accumulating them at different positions along the process and recovering them with arbitrarily high enrichment. The partition coefficients of individual components in e.g. reactive extraction are controlled by creating a pH gradient throughout the process, guiding each component towards its respective accumulation point, where it is recovered with a side stream.

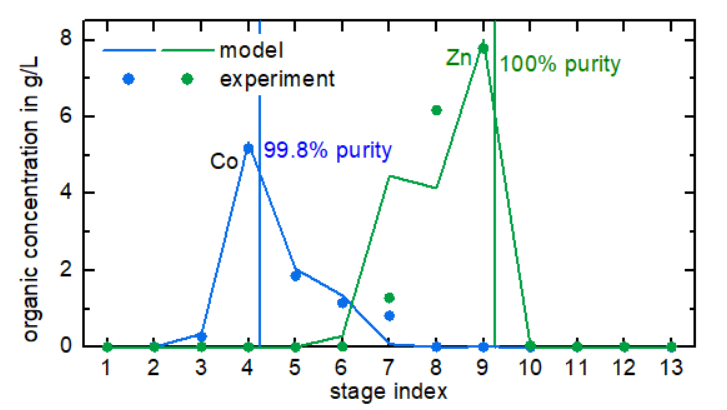

Experimental validation of this process was performed using quasi-continuous experiments with Zn²⁺ and Co²⁺, utilizing D2EHPA as extractant. The experimental setup was designed to simulate steady-state conditions, ensuring that initial concentration profiles matched with simulations. The results shown in Fig. 1. demonstrate that the system reached steady state, with concentration profiles aligning precisely with the simulations. Furthermore, the SisClever process successfully achieved high enrichment factors, with a tenfold increase in metal concentration as compared to the feed concentration. High purity levels were also achieved in the two removal streams, supporting the feasibility of the process for industrial applications.

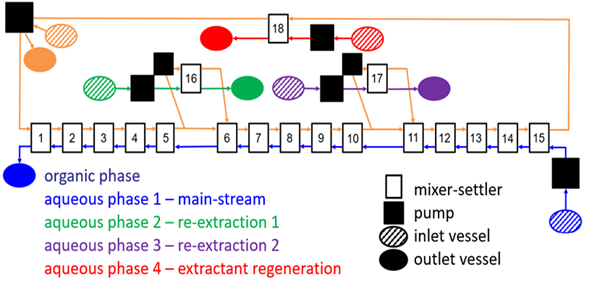

Following these promising results, the goal now is to validate the SisClever process experimentally in continuous mode and to test process control as a first step for technical application of the process. A pilot-scale mixer-settler battery will be taken into operation, which facilitates efficient mass transfer and reduces chemicals consumption compared to traditional processes. The set-up will consist in 18 mixer-settlers MSU 0.5 supplied by MEAB and will be equipped with control of both pH and flow rates, helping to maintain the system in a steady state, guided by simulation results. Initial experiments will focus on two-metal systems such as Co-Zn or Co-Cu. In a second step, the experiments will be extended to systems with up to four metals as the modular structure of the equipment offers operational flexibility, allowing the system to be adapted for various metal separation requirements. The schematic representation of the experimental set up is presented in Fig. 2, where four metals entering in the aqueous phase on stage 15 could be recovered in the aqueous phase leaving respectively stages 1, 16, 17 and 18.

Fig. 1: experimental result compared to simulated steady state. Inlet aqueous concentrations: Co2+: 0.53 g/L, Zn2+: 0.80 g/L, extractant D2EHPA in ELIXORE 25.

Fig. 2: schematic representation of 18 stages mixer settler battery set-up

- Abstract category selection: