Oral Presentation International Solvent Extraction Conference 2025

Mass Transfer Model with Variable Volume Flow in a Solvent Extraction Column (121585)

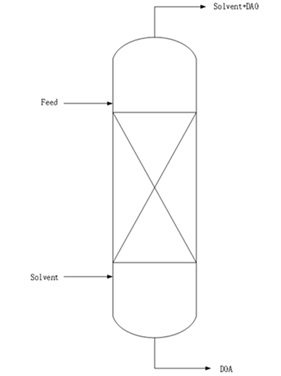

Solvent deasphalting (SDA) is an important separation process of refineries. SDA is a liquid-liquid extraction process according to the molecular type instead of boiling point. Typically, the asphalt is separated from the feedstock (crude or heavy oil) by the aliphatic compounds of the feedstrock dissolving in the solvent (light carbons) while the asphaltenes of the feedstock being left. The deasphalted oil (DAO) could be used as the feedstocks of residue hyrocracking, lube oil, and vacuum gas oil (VGO) conversion. The deoiled asphalt (DOA) could be used as the feedstocks of gasifier, delayed coking, and other asphalts.

In SDA process, the extraction column is the key separation equipment. Due to the complexities of liquid-liquid system, the scale-up of the extraction column still relies on experience. A precise mass transfer model might be very essential to design and scale up the extraction column of SDA process. Different from other extraction systems, the axial velocity distributions of the two phases vary obviously along the height of the extraction column because of the high extraction efficiency. From this point of view, the influence of variable volume flow should be considered in the mass transfer model. Besides that, the extraction system is divided into three components, including DOA, DAO and the solvent. DOA and the solvent are immiscible and DAO could dissolve in both the solvent and DOA.

A method for calculating the volume change of two phases due to mass transfer in the SDA extraction column was proposed. An equation of state (Peng-Robison Equation[1,2]) is used to calculate the local molar volume of each phase along the height of the extraction column according to the axial DAO concentration distributions of the two phases. In this way, the local velocities of the two phases could be calculate.

Combined with the above mentioned variable volume flow model and liquid-liquid equilibrium data in literature[3], a new dynamic axial dispersion model is established. The calculated results fit the experiment data very well with the error less than 5%. The axial dispersion coefficient and mass transfer coefficient are also obtained.

By the model, the axial velocity, holdup and concentration distributions in the SDA extraction column could be obtained. It is helpful to understand the flow and mass transfer characteristics in the SDA extraction column. Moreover, the model could be used to predict the separation performances of SDA extraction columns which is of interest to design and scale up an SDA extraction column.

- Peng D Y, Robinson D B. A New Two-constant Equation of State. Ind. Eng. Chem. Fundam. 1976, Vol. 15(1): 59-64.

- Reid R C, Prausnitz J M, Poling B E. The properties of gases and liquids. 4th ed. New York: McGraw-Hill, 1987.

- Ng S H. Nonconventional Residuum Upgrading by Solvent Deasphalting and Fluid Catalytic Cracking. Energy Fuels. 1997, Vol. 11(6): 1127-1136.

- Abstract category selection: