Oral Presentation International Solvent Extraction Conference 2025

Selective recovery of molybdenum from steel making dust leachate using Cyanex 600 (121590)

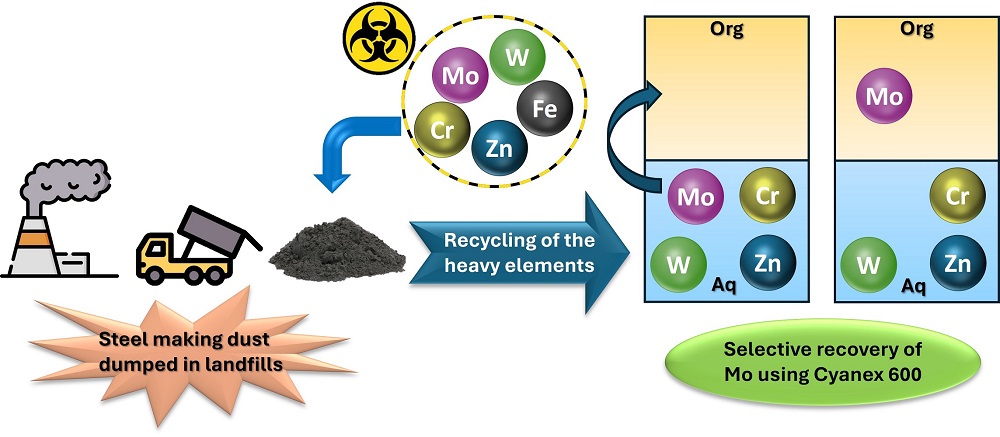

Molybdenum has recently gained interest as it is a critical and costly metal that plays a vital role in many technologies such as steel and aerospace industries. However, concerns arise regarding the long-term availability of molybdenum resources to sustain its increasing demand. The recent studies suggest that exhaustion of molybdenum could arrive within a century. To prevent this, the focus on molybdenum recycling has been increasing over the past years. A previous work focused on steel making dust to selectively leach and recover Mo from Zn and Fe with alkaline solutions.1 Herein, this work presents the development of a recycling process of molybdenum leachate from steel making dust using solvent extraction with the Cyanex 600 as the extractant. To the best of our knowledge, no published studies have assessed molybdenum extraction in an alkaline medium using Cyanex 600. In this work, two scenarios were explored: (1) the original leachate containing Mo, Cr and W, and (2) a modified leachate with added Zn. Various parameters such as the concentration of the extractant, pH, shaking time, temperature, and the organic to aqueous ratio were investigated. Results demonstrate that molybdenum can efficiently be extracted from the original leachate in an alkaline media without any pH adjustment. Selective and efficient recovery of Mo has been possible for pH above 2: %E>80~90% for Mo with low co-extraction of Cr and W (<10%). In the second case, the addition of Zn compromises the selectivity at alkaline pH but optimizing the parameters prevents that. The process proposed is environmentally friendly, effective, fast and does not require a large amount of extractant. In the second scenario the best parameters were found to be an extractant concentration of 0.1 or 0.5 M, an organic to aqueous ratio below 1, an extraction time of 10 min, at pH ≈ 1.5, and at room temperature. This approach offers an efficient pathway for molybdenum recovery, with potential applications in other industries and waste streams.

1. Petranikova, M., Ssenteza, V., Lousada, C. M., Ebin, B. & Tunsu, C. Novel process for decontamination and additional valorization of steel making dust processing using two-step correlative leaching. Journal of Hazardous Materials 384, 121442 (2020).

- Abstract category selection: