Oral Presentation International Solvent Extraction Conference 2025

Membrane Assisted Rare Earth Separation by Solvent Extraction. Laboratory and Continuous Pilot Plant Testing (122688)

Solvent extraction (SX) using mixer-settlers is presently the leading technology for the commercial separation of rare earth elements worldwide. While this well-established technology boasts numerous advantages, traditional SX processes have several significant drawbacks. These include large solvent inventories and large plant footprints, primarily due to the requirement for significant settler area.

Over the past several decades, various alternative technologies have been actively researched and developed to address some of the limitations of traditional mixer-settler based solvent extraction processes. One such technology is membrane-assisted solvent extraction (MSX), which utilises different types of membrane contactors, predominantly those with membranes embedded as bundles of small-diameter hollow fibers (HF). HF contactors offer certain advantages over traditional mixer-settlers. They provide a fully enclosed system, which is essential for minimising diluent evaporation and making the process suitable for handling toxic and volatile organics. Furthermore, the absence of motors and other moving parts in HF contactors further reduces the risk of mechanical failures.

This study aimed to evaluate the effectiveness of hollow fiber membrane contactors in the recovery and separation of rare earth elements (REEs), and to compare their performance with conventional solvent extraction (SX) processes using mixer-settlers.

The system chosen for the study was the group separation of light rare earth elements, La-Nd (LREE), from the middle/heavy rare earth elements, Sm-Lu, Y (M/HREE), typically targeted in the first circuit of RE refineries. The study was carried out in two phases:

- Laboratory study using a single module in a batch configuration,

- Continuous pilot study using multiple modules.

Laboratory studies

A series of batch laboratory experiments were conducted using a single Liqui-Cel™ EXF-2.5×8 hollow fiber (HF) contactor in non-dispersive solvent extraction (NDSX) configuration, to examine the impact of various parameters on the efficiency of REE extraction and separation in a membrane-assisted process. This study provided basic data for modelling a continuous, multi-stage membrane-assisted REE separation process.

Continuous pilot plant study

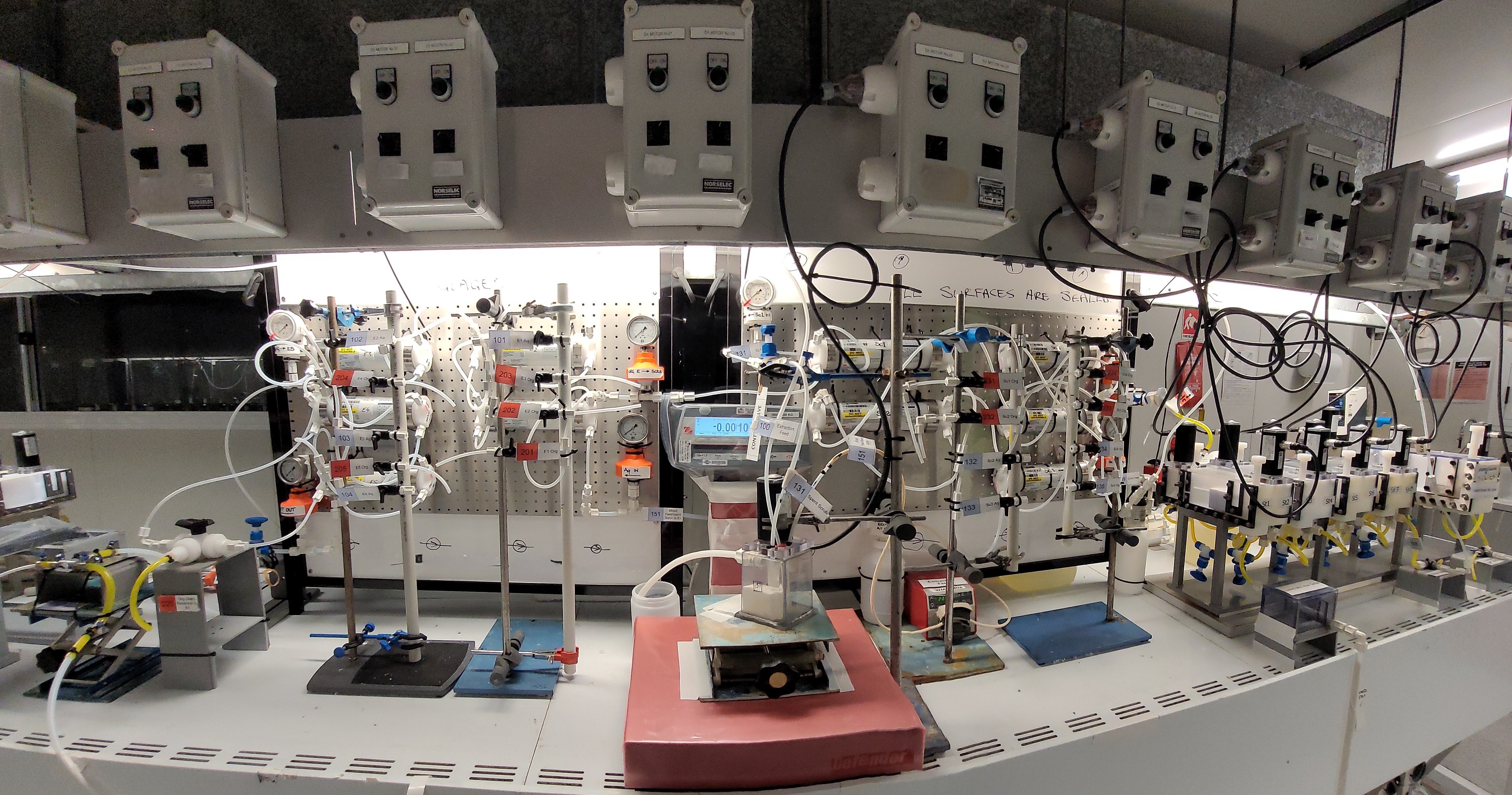

A multi-stage solvent extraction circuit comprising of ten Liqui-Cel™ EXF-2.5×8 hollow fiber (HF) and nine mixer settler contactors was set-up and operated continuously for 135 hours. This included five extraction and five scrub HF modules, and one saponification and eight strip mixer-settlers, all operated in the once-through, counter-current mode. Rare earth elements from a synthetic mixed REE chloride feedstock containing 130 g/L REE with a molar LREE:MREE:HREE ratio of ~1:0.01:0.001, were extracted using the commercial extractant P507 in an aliphatic diluent. The solvent was saponified with NaOH solution.

The HF assembly demonstrated exceptionally stable operation throughout the continuous pilot plant trials, consistently demonstrating its ability to maintain reliable performance over extended period. The efficiency of the HF modules in the NDSX configuration, however, was found to be lower than conventional mixer-settlers when a direct comparison was made on the basis of equipment unit volume.

Continuous Pilot Plant Trial Set-up

- Abstract category selection: