Oral Presentation International Solvent Extraction Conference 2025

Production of cobalt sulphate from cobalt chloride by solvent extraction with Cyanex 272 (130759)

Selective separation of cobalt by solvent extraction is an essential step in the production of high purity cobalt sulphate for use in battery cathode manufacturing. Typically, the process commences with a cobalt sulphate solution containing nickel and manganese, and a cationic solvent extraction process is employed using Cyanex 272, D2EHPA or Versatic Acid 10 (Sole 2018). This would generally require the use of sodium hydroxide, sodium carbonate, or ammonium hydroxide as a neutralising agent. The sodium reagents result in the formation of sodium sulphate, which requires concentration, crystallisation, and costly disposal. The ammonium reagents can be recycled, but require significant increases in capital equipment and operating costs.

Cobalt Blue has developed a robust method for selective solvent extraction of cobalt using limestone as the neutralising agent. Commencing with a chloride aqueous media, the acid transferred from the organic phase during the extraction step is neutralised by limestone. The calcium deports from the extraction step as calcium chloride, and is subsequently precipitated as high purity calcium sulphate due to the addition of sulphuric acid. The calcium sulphate is readily filterable, and can be used a landfill cover, or industrial re-use applications.

Initial testwork focused on comparing various extractants including Cyanex 272, D2EHPA, Versatic Acid 10, LIX 84, LIX 860, and their combinations. Both limestone and lime were trialled. Limestone could control the pH of the extraction stage to pH ~6, whereas the lime could control pH ~9-10. While the lime could control the extraction stage to a more basic pH (and thus drive more metal extraction), unintended and unavoidable formation of metal hydroxides occurred (e.g. cobalt and nickel hydroxide precipitates at pH >6.5). These phases did not readily re-dissolve during the extraction stages, even when contacted with incoming aqueous feed solution at much lower pH values (e.g. pH 2-4). In contrast, no precipitates were formed when using limestone, resulting in effectively complete dissolution of solids in the extraction stage.

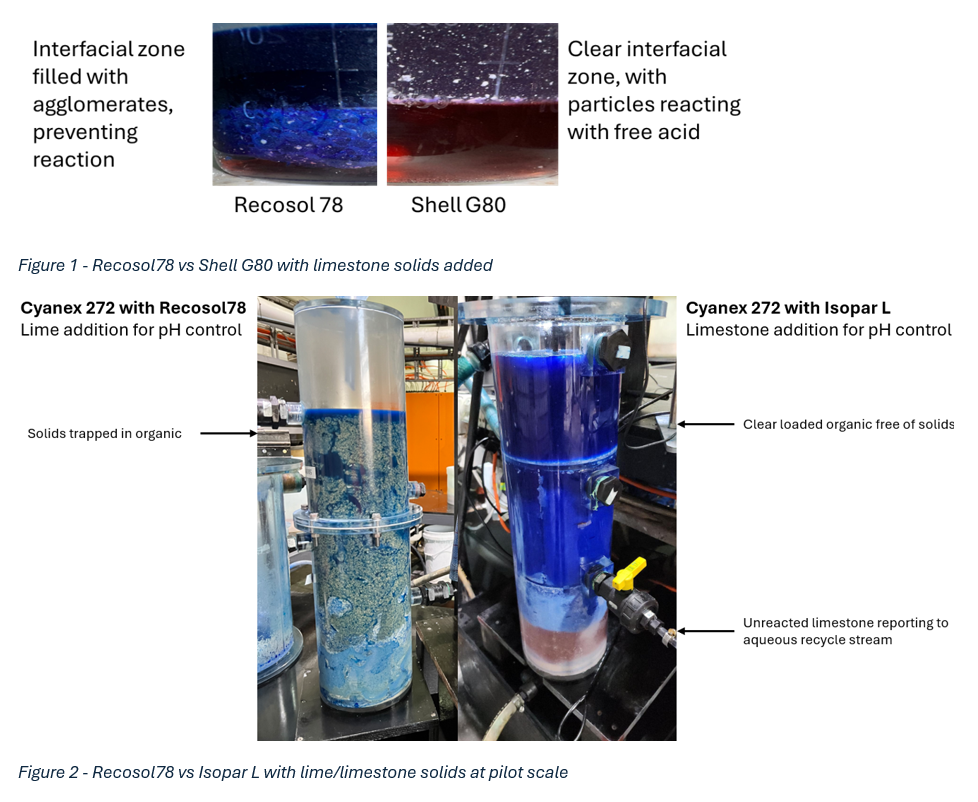

A pilot circuit was designed and operated at the Broken Hill Technology Centre. Cyanex 272 was used as the extractant, diluted with Isopar L (an Exxon product). Both Isopar L and GTL G80 (a Shell product) were successfully trialled as diluents. These diluents are long-chain isoparaffins, which minimise the formation of hydrogen bonding to the limestone, compared to the use of more traditional diluents like Recosol 78 or Shellsol 2046. A few examples of this phenomena are shown below in Figure 1 and Figure 2.

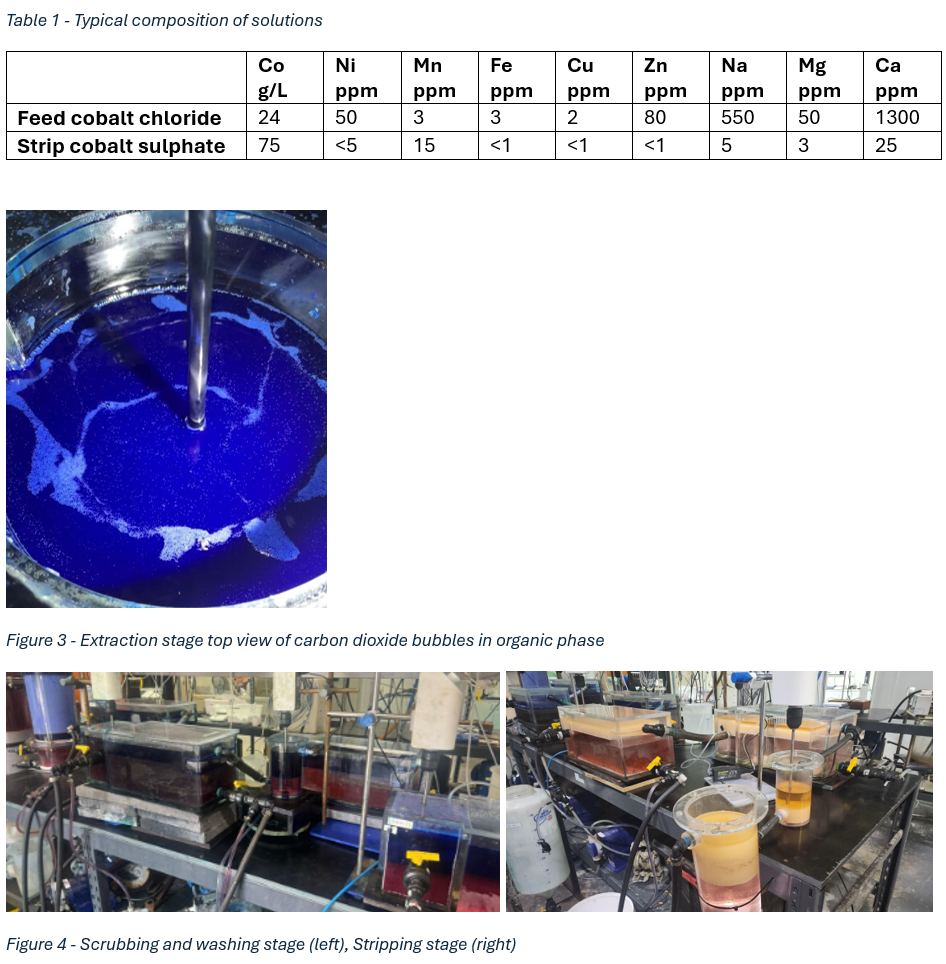

The circuit was operated for 100 hours. At steady-state conditions, approximately 1.5 kg/hr of cobalt was transferred from the starting cobalt chloride solution (purified leach solution) to a cobalt sulphate strip solution. The typical composition of the feed and strip solutions are given below in Table 1.

The pilot circuit continues to be optimised, and Cobalt Blue intend to commercialise the circuit as part of the Kwinana Cobalt Refinery. The refinery throughput is expected to be ~350-400 kg/hr of cobalt, which is nominally 250 times scale-up from the pilot plant. Photos of the pilot plant are shown below in Figure 3 and Figure 4.

- Sole K (2018) The evolution of cobalt–nickel separation and purification technologies: Fifty years of solvent extraction and ion exchange. In: Davis et al. (eds) Extraction 2018, The Minerals, Metals and Materials Series, p 1167-1191

- Abstract category selection: