Oral Presentation International Solvent Extraction Conference 2025

SisClever Process: Simultaneous Recovery Of Metals From Ore Or Waste To High Purity And High Concentration Via Solvent Extraction – Principle And Applications (121008)

Context

Sustainability requires the systematic recycling of materials, such as discarded lithium batteries or electronic waste, which contain various valuable components in varying concentrations. A process should be able to respond to this variation in the feed stream. It is also desirable to be able to separate low-concentration components with high purity and concentration. Complex and multi-step hydrometallurgical separation processes are currently operated to meet these challenges.

SisClever process

As a solution to these complex separation processes, the SisClever process has been developed. It is a new general process concept applied here to reactive solvent extraction, for the separation of valuable metals as an example. The idea is to establish an individual accumulation region for each component to be separated in the counter-current process. This is achieved by establishing a dedicated pH-profile along the process. At each accumulation region, the respective component is removed with a side stream. The process idea is illustrated in Fig. 1. The process idea has been validated experimentally.

![]()

Fig. 1: SisClever process idea for a three-component system

By appropriate design, in principle, arbitrary purity and arbitrary concentration can be reached, limited only, for example, by solubility. Several metals can therefore be recovered simultaneously as pure fractions in a single process. Even components with a low feed concentration can be recovered with high concentration.

Applications

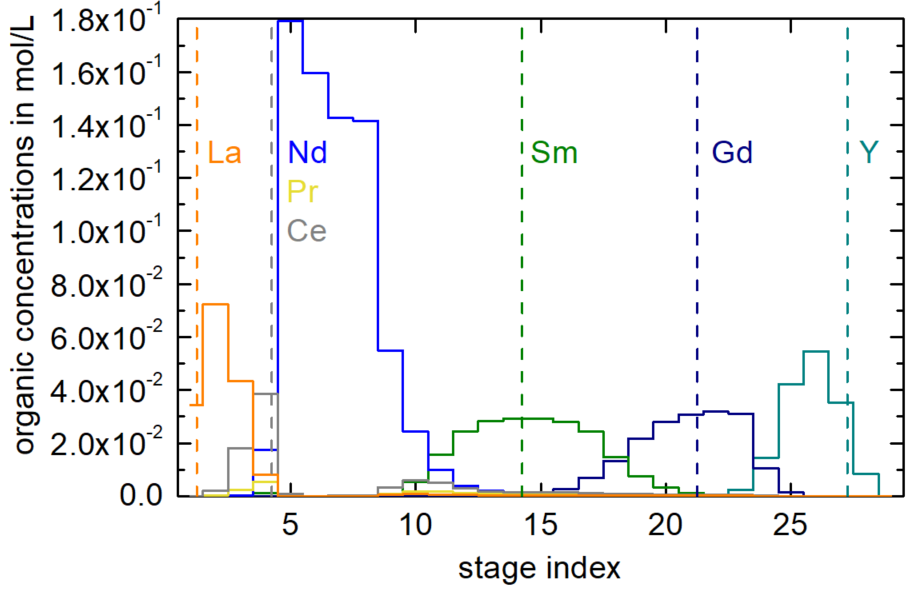

A simulation tool has been developed to predict the component behavior throughout the process. This tool enables the pH-profile to be optimized according to various aspects chosen by the user, such as product purity or acid and base consumption. The SisClever process was applied to several systems typical of metal recycling, such as REE, Li batteries, brines or Nd magnets. The simulations were carried out based on equilibrium data obtained from the literature. The example of REE separation is shown in Fig. 2, where a mixture of 7 metals is separated into 5 side streams, represented by dashed lines. The pH-profile that enables this separation has been optimised to achieve high removal purities. This case study was taken from Srivastava (2021), where an optimized conventional process with 104 stages process is proposed for the separation of these elements, while only 29 stages achieve even better results with the SisClever process.

Fig. 2: metal concentration profiles in the organic stream for REE separation. The partial side removal streams are represented by dashed lines

- V.K. Srivastava, Modeling of Rare Earth Solvent Extraction Process Modeling of Rare Earth Solvent Extraction Process for Flowsheet Design and Optimization for Flowsheet Design and Optimization, Ph.D. Thesis, University of Kentucky 2021.

- Abstract category selection: