Oral Presentation International Solvent Extraction Conference 2025

Optimising the Manufacture of DEHiBA Through Industry 4.0: Continuous Purification Optimisation with Coalescing Separators (122635)

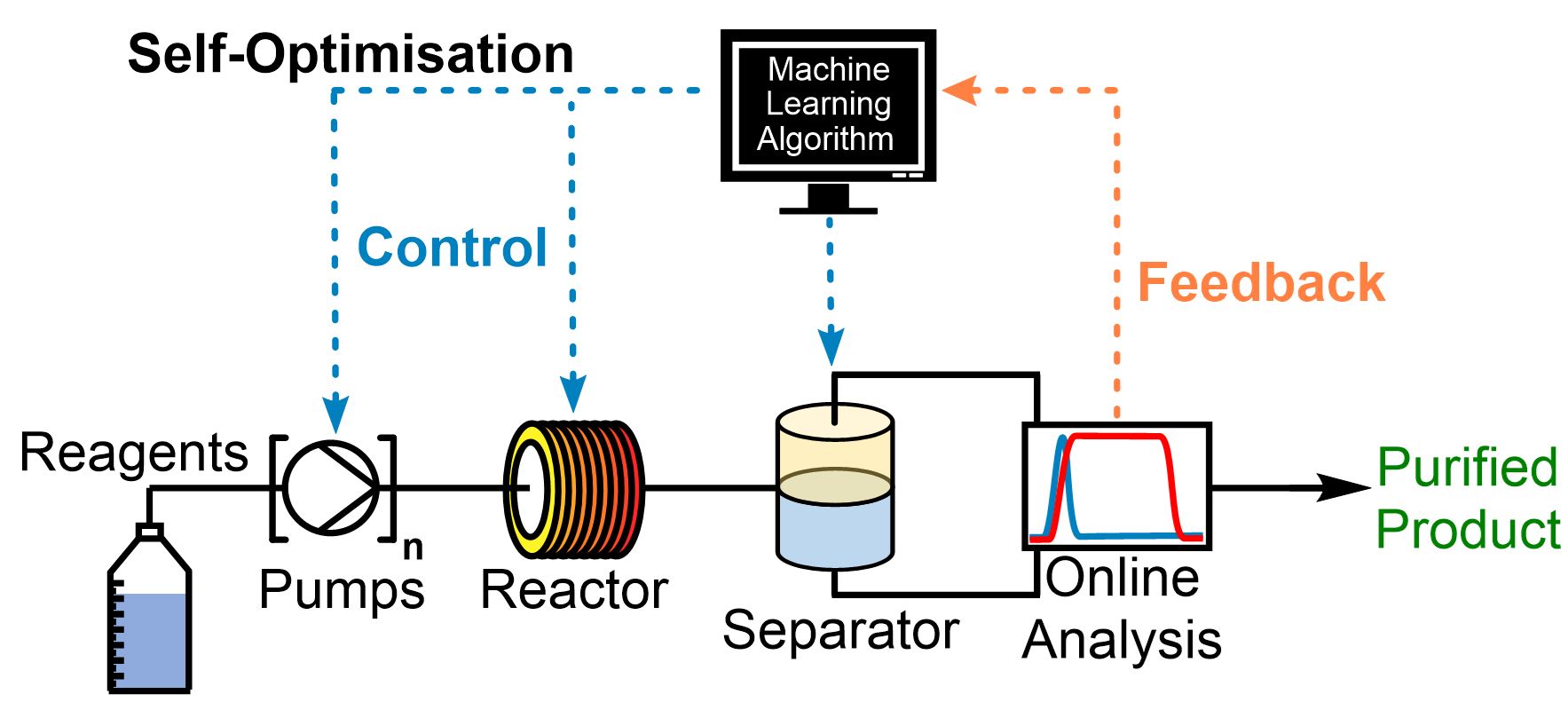

Advanced nuclear reprocessing flowsheets are heavily reliant on specialised organic ligands for their selective chelation properties that facilitates the extraction and recovery of troublesome and valuable radionuclides from used nuclear fuel. This reduces the burden of radiotoxic waste whilst enhancing the sustainability of nuclear fission through the recycle of elements from across the periodic table. The specialist nature of highly tailored ligands such as DEHiBA, TODGA, DMDOHEMA, and BTBPs lends them to being high-cost research materials. This cost barrier is restrictive to researchers, especially when considering the required volumes for pilot-plant testing of advanced flowsheets to further the technology readiness level. The rise of industry 4.0 enhances the optimisation of chemical processes, streamlining the development of chemicals by integrating machine-learning with automated manufacture platforms to maximise key process metrics in minimal experiments.

By exploiting the power of machine-learning and automation with flow chemistry, this work employs an automated, self-optimising flow platform to facilitate the optimisation of process metrics such as reagent cost, productivity and purity for the manufacture of pure DEHiBA. This approach has identified an optimal, scalable, cost effective manufacture route to DEHiBA (N,N-di-(2-ethylhexyl)isobutyramide), through the optimisation of multiple synthetic pathways and purification routes. Such technology facilitates the rapid optimisation of chemical transformations in as little as a day. The resulting product of these optimisations is a synthetic route that offers production rates upwards of 70 kg L-1 h-1 of DEHiBA and the production of >99.9% pure DEHiBA with a total yield of 97%, no solvent is required to control the reaction, granting a process mass intensity of 1.29 g g-1 for the crude DEHiBA. We therefore have a methodology and lab-scale platform capable of optimising the manufacture of pure ligands of interest, reducing cost barriers to research. The University of Leeds now has the capability to manufacture litres of DEHiBA in the Institute of Process Research and Development (IPRD).

Through the IPRD and this work a coalescing separator has been developed and tested, proving itself to be highly versatile and capable of handling complex liquid-liquid extraction conditions such as solids and hard to break emulsions. The coalescing separator used is suitable for lab-scale extractions/purifications minimising material consumption and footprint, but is scalable and applicable across many sectors in the future.

Ultimately, we have tested the performance of DEHiBA from this manufacture route for the extraction of uranium(VI) confirming against data in the literature. In the future we hope to test DEHiBA across a range of scales and conditions both in batch and flow with annular centrifugal contactors in the active lab at Leeds. This talk discusses and builds on work in our recent publications.1,2

- T. Shaw, A. D. Clayton, R. Labes, T. M. Dixon, S. Boyall, O. J. Kershaw, R. A. Bourne, and B. C. Hanson, Reaction Chemistry & Engineering, 2024.

- T. Shaw, A. D. Clayton, J. A. Houghton, N. Kapur, R.A. Bourne, and B. C. Hanson, Separation and Purification Technology, 2025

- Abstract category selection: