Oral Presentation International Solvent Extraction Conference 2025

Intensified solvent extraction of samarium in small channels and scale out (122670)

Introduction

Modern and emerging technologies depend on critical metals; to secure their supply chains it is important to recover them from waste materials. One of such critical elements is samarium, which finds applications in nuclear technologies such as neutron capturing, probe applications due to its unique luminescent properties, and permanent magnets [1]. The retrieval of critical metals from waste can be achieved with hydrometallurgical methods, where solvent extraction is a main operation. Small channels contactors have been shown to intensify solvent extractions [2]. To overcome the low throughput of these system, numbering-up of the small channels has been proposed where many channels are used in parallel, while the intensification advantages of small channels are maintained [3, 4].

In view of these, the intensified small channel solvent extraction of samarium from aqueous solutions was investigated in this work and the potential for scale up was demonstrated. The hydrodynamic behaviour of the two phases and the extraction of samarium from a chloride solution into an organic phase, with di-(2-ethylhexyl) phosphoric acid (D2EHPA) as the extractant, were initially studied in single channels. For the scale-out, a manifold was designed based on a resistance network model [3], enabling multiple single channels to operate in parallel. The influence of flow rates, phase volume ratio, and fluid properties on flow and extraction across the manifold parallel channels were investigated. Flow regimes were studied with high speed imaging and optical sensors.

Experimental Procedure

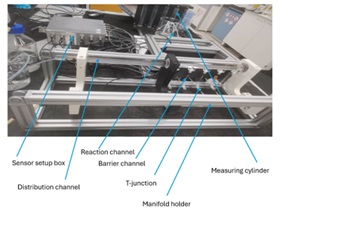

For the experiments, water and kerosene were used as the test fluids. Furthermore, extraction of samarium (III) was studied from an aqueous HCl solution to a solution consisting of kerosene as the diluent and di-(2-ethylhexyl) phosphoric acid (D2EHPA) as the extractant. Studies were carried out in the plug flow regime where intensification is large while it can be easily modelled. To ensure plug flow, the volumetric flow rate and the phase volumetric ratio (Org/Aq) ranged from 0.01- 20 ml/min and 0.5 – 2 respectively. The test section was a 2 mm PTFE tube. For the scale out five channels were operated in parallel [3]. The diameter of the distribution, barrier and reaction channels were designed to be 20 mm, 0.508 mm, and 2 mm, respectively, while the length of the barrier and reaction channels were100 mm and 735 mm, respectively (see Figure 1). The total volumetric flow rate of the two-phase mixture and the volumetric ratio of the phases over a ranges of 0.6 – 20 ml/min were measured by collecting the mixtures from the outlets of each test channel in measuring cylinders. The characteristics of the plug were investigated in the test channels using high-speed camera (Phantom v1310) imaging and FCI-InGaAs-500 photodiode sensors.

Results and Discussion

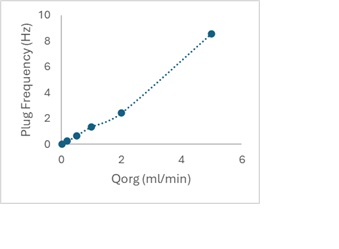

The optical sensors were first validated against the high-speed camera images in the single channels and then used in subsequent experiments to obtain the characteristics of the plug flow both in single channels and in the manifold channels. As can be seen in Figure 2, the frequency at different volumetric flow rates of the plugs increases with increasing the phase volumetric flow rate.

Fig. 1. Photo of the scale-out manifold setup.

Fig. 2. Effect of volumetric flow rate at a volumetric phase ratio of 1 on the plug frequency

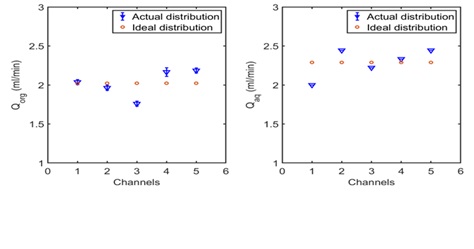

The organic and aqueous phase flow rate distributions over the five channels for a nominal total volumetric flow rate of 10 ml/min for each phase are given in Figure 3. As it can be seen, in general the distribution is good, while the aqueous phase is more uniformly distributed among the five channels than the organic one.

Fig. 3. Volumetric flow rate distribution across the five channels at volumetric flow rate of 10 ml/min

Solvent extraction experiments were carried out in the single channels and the scale out manifolds. The results showed that in the scale out geometries, flows were uniformly distributed among the channels ensuring that the extraction behaviour is also similar among the channels.

- Abstract category selection: