Oral Presentation International Solvent Extraction Conference 2025

Group Actinide Separation Process (GrASP): A Single-Solvent Process for U/TRU Recovery and Minor An/Ln Separations Using HEH[EHP] and T2EHDGA (123148)

Background

Commercial solvent extraction technology for the recovery of uranium and plutonium from spent nuclear fuel (SNF or UNF) is based on the PUREX process, using tributyl phosphate in aliphatic diluent. Although PUREX and its basic modifications can be highly efficient for U, Np, and Pu recovery, they suffer some inherent drawbacks, including poor proliferation resistance and a complete inability to manage the minor actinides americium and curium. Solving these two problems in a cost-effective manner is a necessary challenge in improving the safety and sustainability of a closed nuclear fuel cycle.

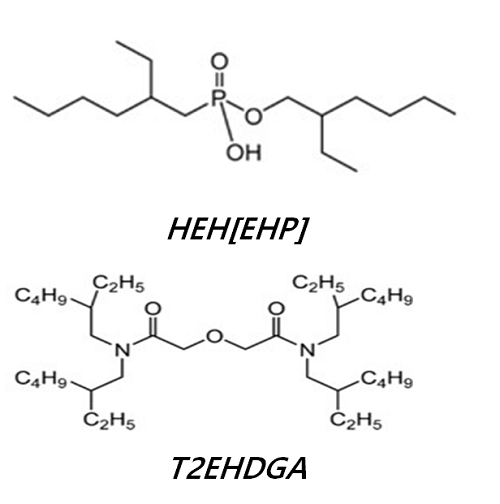

Work on these problems in Europe has been expansive, and a number of advanced concepts have been put forth: CEA- and Euro-GANEX, CHALMEX, TRU-SANEX, etc. Although these represent positive progress, uncertainty remains [1]. Work in the United States has been limited. In 2014, the Actinide-Lanthanide Separation (ALSEP) concept was introduced in US, deploying an acidic ligand (2-ethylhexylphosphonic acid mono-2-ethylhexyl ester, HEH[EHP]) and a neutral ligand (N,N,N′,N′-tetra(2-ethylhexyl)diglycolamide, T2EHDGA) in combination to achieve separation of Am and Cm from the fission products, including lanthanides, of PUREX raffinate [2, 3]. ALSEP has since been demonstrated successfully multiple times at different scales [4, 5]. In 2021, early work began at the University of Nevada, Las Vegas to expand the scope of ALSEP to include major as well as minor actinides and to characterize active species in the various extractions. That work has evolved into GrASP (Group Actinide Separation Process), a US-based, single-solvent flowsheet for the group recovery of U, Np, and Pu and the separation of Am and Cm from fission products.

Methods

We report here proof-of-principle experiments demonstrating the viability of GrASP, consisting principally of batch contacts using a simulated SNF (non-rad FPs + U + Np + Pu + Am) to test the concept as a whole. The process behaviors of individual actinides have also been comprehensively surveyed with batch contacts.

Many of the challenges in GrASP were similar to those that initially faced ALSEP, and modifications of ALSEP’s solutions have largely proven effective for obstacles in GrASP; consequently, and to the benefit of the process as a whole, many of the same reagents appear. In addition to the working ligands HEH[EHP] and T2EHDGA, the process as currently formulated uses acetohydroxamic acid (AHA), cyclohexanediaminetetraacetic acid (CDTA), diethylenetriaminepentaacetic acid (DTPA), oxalic acid, and phosphoric acid, with multiple other reagents being actively explored for process refinement.

Results

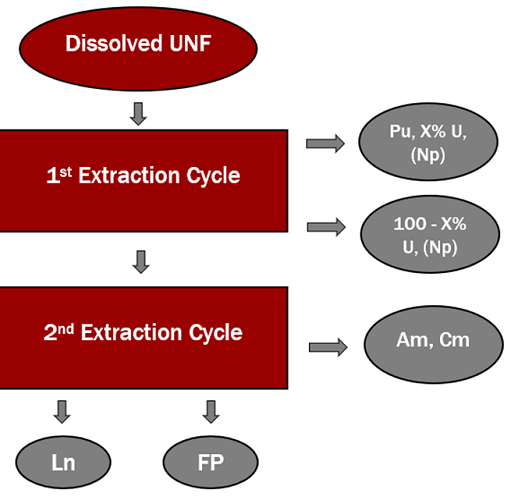

GrASP is in essence a single-solvent tandem group extraction process. To begin, HEH[EHP] and T2EHDGA in n-dodecane is contacted with dissolved SNF containing CDTA in a phase ratio dictated by the ligand/U ratio; U, Np, and Pu are efficiently separated from all fission products save molybdenum. Mo and trace trivalent elements are subsequently scrubbed from the solvent in a series of AHA contacts. The major actinides can then be stripped together in a single contact with phosphoric acid, or Pu, Np, and a smaller fraction of the uranium can be slowly stripped in a series of oxalic and DTPA contacts prior to the stripping of bulk U. The solvent can then be regenerated and contacted with the initial raffinate in what is more or less the established ALSEP flowsheet to partition Am and Cm from Ln and FPs.

0.50M HEH[EHP] + 0.05M T2EHDGA can be loaded to approximately 50g/L U. Metal loading can be increased by raising the HEH[EHP] concentration to 0.75M at the cost of poorer scrubbing and stripping kinetics. As is, the U/Np/Pu-loaded solvent appears to be highly resistant to stripping, including conventional reductive stripping of Pu; although this may necessitate the use of a harsher strippant like phosphoric acid, it makes GrASP relatively proliferation resistant. The recovery of the actinides in two groups, major and minor, and the ability to control the U/Pu ratio of the product to a degree offers more flexibility than existing group extraction concepts and situates GrASP nicely to integrate with any future closed fuel cycle.

- Authen, TL; et al. “An overview of solvent extraction processes developed in Europe for advanced nuclear fuel recycling, Part 2—homogeneous recycling.” Separation Science and Technology. 2022.

- Lumetta, GJ; et al. “The Actinide-Lanthanide Separation Concept.” Solvent Extraction and Ion Exchange. 2014.

- Gelis, AV; et al. "Actinide Lanthanide Seperation Process--ALSEP." Industrial & Engineering Chemistry Research. 2014

- Gelis, AV; et al. “Closing the Nuclear Fuel Cycle with a Simplified Minor Actinide Lanthanide Separation Process (ALSEP) and Additive Manufacturing.” Nature—Scientific Reports. 2019.

- Wilden, A; et al. “Countercurrent Actinide Lanthanide Separation Process (ALSEP) Demonstration Test with a Simulated PUREX Raffinate in Centrifugal Contactors on the Laboratory Scale.” Applied Sciences. 2020.

- Abstract category selection: