Oral Presentation International Solvent Extraction Conference 2025

Applying Image Analysis to Evaluate Residence Time Distribution for Emulsion-flow Extractor (122666)

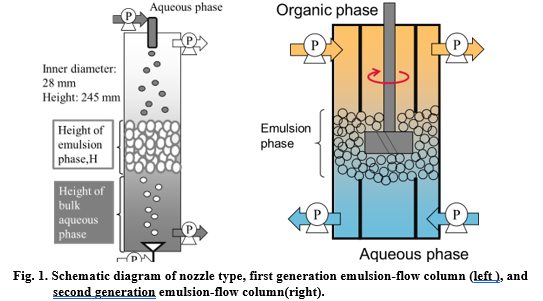

A novel extractor known as emulsion-flow column was developed by Naganawa et al. and the exceptionally high throughput for the column volume was proven experimentally for the extraction of Yb and U using D2EHPA[1]. Thanks to the rapid coalescence of droplets of both aqueous and organic phases, the throughput of aqueous phase was 13 times higher than the conventional mixer settlers. The first generation of the extractor equipped a nozzle for each aqueous and organic phase, respectively. The point of the operation is supplying both phase as droplets and let them flow counter currently. The flow of these droplets caused a layer of droplets in the middle of the column. The layer was called emulsion phase and droplet coalescence proceeds in this layer. The authors reported that the mass-transfer rate in this type of the column is higher than the spray columns and lower than the packed columns [2]

As shown in Fig. 1, the second generation of the emulsion-flow extractor has been recently developed. Nozzles were removed and an impeller was installed near bulk interface instead. Stirring impeller helped to create droplets of both phases and also to enhance mass-transfer. Interestingly, drop coalescence is enhanced under stirring condition, and the two-phase flow stably in both counter-current and as well as parallel ways. The present study aims at elucidating the flow behaviour of both phases in the column and also reasons for both successes in vigorous agitation and rapid droplet coalescence. Experiments were performed under various conditions of flow rates of oil and aqueous phases. By applying dye tracers to visualize droplets behaviour in the column.

In the experiment, deionized water was used for the aqueous phase and a mixture of PC-88A and naphthenic solvent (EXXSOL D80) for organic phase. The organic phase was fed to the top

of a rectangular column made of transparent PVC, 85 mm wide, and 170 mm high, and the aqueous phase was fed to the bottom of the column for counter-current contact. Right after stirring the both phases, the emulsion phase, the layer of droplets appeared.

After reaching a steady state, the droplet behaviour in the column was recorded with a digital camera (DSC-RX100M7, SONY) and droplet diameter was measured with ImageJ. The turbidity at the outlet of the aqueous and oil phases was also measured with a turbidimeter (2100P, HACH).

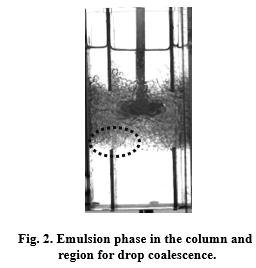

Figure 2 represents a picture of emulsion phase when the column was operated at 100 mL/min organic phase, 50 mL/min for aqueous phase and 350 rpm of rotating speed. The movement of droplets were carefully observed with naked eyes and video images. Many droplets moved in the radial direction and accumulated near the wall or plates surrounding the impeller. In the dotted circle shown in Fig. 2, droplets disappeared due to the coalescence. Visual observation revealed that both organic phase droplets and aqueous phase droplets were present in the emulsion phase.

Droplet size distribution was measured with and without extractant system. The presence of PC88A lowered the number of large drops. Only a little effect of PC88A was found on the droplet size within the range of 1.0 to 2.0 mm. At the outlet of the aqueous phase, turbidity was analyzed to check the progress of droplet coalescence. No fine droplets of organic phase were observed and the turbidity value was about 0.2 NTU which was small enough to assure successful drop coalescence. The fact indicates that stirred type emulsion-flow extractor provides effective flow field for liquid-liquid contact in a compact apparatus.

- Abstract category selection: