Oral Presentation International Solvent Extraction Conference 2025

Scale-out of intensified liquid-liquid extractions in small channels for iron recycling from spent magnets (122715)

The Neodymium Iron Boron (NdFeB) magnet is one of the most essential and critical components of both wind turbines and electrical vehicles, where it is used in their motors or generators to produce strong magnetic fields [1]. The increasing demand for the magnet requires large amounts of rare earth metals and iron for manufacturing. Iron is a less scarce resource in the near future compared with rare earth metals to be recycled from spend magnets, but the separation of iron from spent magnets is essential in producing iron-free solutions for recycling other rare earth metals such as Nd and Dy.

Among the common metal separation methods such as precipitation [2], ion exchange [3,4], and adsorption [5], solvent extraction is widely used because of many advantages such as low energy consumption and selectivity. With various applications such as selective separation of actinides/lanthanides from spent nuclear fuel [6] and intensified recycling of rare earth metals [7], liquid-liquid solvent extractions in small channel contactors has shown great potential in efficiency and sustainability compared to the conventional batch systems. Reported extraction efficiencies increase above 90% in short residence times of a few seconds. Also, the small size of these contactors and the well defined flows can facilitate a modular design and integration with digitalised automation systems such as optical, electornic and ultrasound sensors. Despite all the benefits of small channel contactors in mass transfer and control, the industrialised production is still limited mainly because of the low throughput.

To address this issue without losing the benefit of enhanced mass transfer rates in small channels, scale out approaches have been proposed where many small channels are operated in parallel. In these configurations it is important that the flow conditions, flow rates and volumetric flowrate ratios, in all parallel channels are similar. This can be achieved with appropriately designed flow distributors. A design approach is based on resistance network modelling (RNM) which exploits the similarity of flows with electric currents [8]. In this work, we demonstrate the recycling of iron by using intensified liquid-liquid solvent extraction in a scale-out small channel contactor system. The iron extraction was compared in stirred vessels and small channel contactors. The flow distribution in the scale-out system is measured in terms of both volume ratio of the two fluids and total flowrate in each of the small channel contactors. The extraction performance is discussed in terms of extraction efficiency and scalebility.

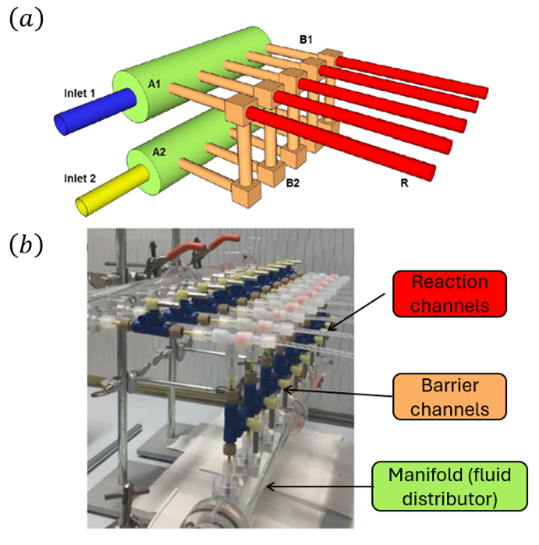

Iron extraction experiments were conducted in stirred vessels and small channel contactors, respectively. The organic phase, consisting of kerosene (diluent), Tributyl phosphate (TBP, extractant), and Di(2-ethylhexyl)phosphoric acid (D2EHPA, co-extractant), was brought into contact with a 0.5M FeCl3 solution in 1-3M HCl. The stirring time in the stirred vessels varied from 15 min to 1 hr at a stirring speed of 600 rpm, while the residence time in the small channel contactors varied from 30s to 90s (corresponding to 0.6-1.8 m channel length with a diameter of 2 mm). A flow distributor with 5mm diameter was designed for 5 small channel contactors based on the RNM model [8].

With a ratio of 1:3 TBP: D2EHPA, a 99% extraction percentage of iron was found in the stirred vessels after 45 mins, indicating a partition coefficient of around 100. The extraction efficiency in small channel contactors reached over 90% within 75s. The schematic for the RNM model is shown in Figure 1a and the geometry of the scale-out device is shown in Figure 1b.

When the input flow rate ratio of the two phases deviates from 1, the fluid distribution is more uniform among the channels. When the overall flow rate is increased, the fluid maldistributionis decreased. An example of flow distribution at an ratio of the aqueous flow rate to the organic flow of 1.15 can be found in Figure 2a. The extraction efficiency reaches above 80% as shown in Figure 2b. Compared with extraction in a single channel, it was found that the extraction percentages in the scale out design is similar with a +/- 10% error, which correlates to the degree of fluid maldistribution. Our scale-out design methodology can be used to design manifolds with more than five channels and increase the throughput for extractions.

- [1] Kumari A, Sahu SK. A comprehensive review on recycling of critical raw materials from spent neodymium iron boron (NdFeB) magnet. Sep Purif Technol 2023;317:123527. https://doi.org/10.1016/J.SEPPUR.2023.123527.

- [2] Hu P, Zhang Y, Liu T, Huang J, Yuan Y, Yang Y. Separation and recovery of iron impurity from a vanadium-bearing stone coal via an oxalic acid leaching-reduction precipitation process. Volume 180, Pages 99 - 106 2017;180:99–106. https://doi.org/10.1016/j.seppur.2017.02.053.

- [3] Pheasey C, Angeli P. Intensified Nd extraction in small channels for NdFeB magnet recycling. Sep Purif Technol 2023;311:122958. https://doi.org/10.1016/J.SEPPUR.2022.122958.

- [4] Bian Z, Feng Y, Li H, Wu H. Efficient separation of vanadium, titanium, and iron from vanadium-bearing titanomagnetite by pressurized pyrolysis of ammonium chloride-acid leaching-solvent extraction process. Sep Purif Technol 2021;255:117169. https://doi.org/10.1016/J.SEPPUR.2020.117169.

- [5] Karami H. Heavy metal removal from water by magnetite nanorods. Volume 219, Pages 209 - 216 2013;219:209–16. https://doi.org/10.1016/j.cej.2013.01.022.

- [6] Tsaoulidis D, Mamtora M, Pineda M, Fraga ES, Angeli P. Experimental and CFD scale-up studies for intensified actinide/lanthanide separations. Chemical Engineering and Processing - Process Intensification 2021;164. https://doi.org/10.1016/j.cep.2021.108355.

- [7] Javed A, Singh J. Process intensification for sustainable extraction of metals from e-waste: challenges and opportunities. Environmental Science and Pollution Research 2023 31:7 2023;31:9886–919. https://doi.org/10.1007/S11356-023-26433-3.

- [8] Garciadiego Ortega E, Tsaoulidis D, Angeli P. Predictive model for the scale-out of small channel two-phase flow contactors. Chemical Engineering Journal 2018;351:589–602. https://doi.org/10.1016/j.cej.2018.06.020.

- Abstract category selection: